| Prowler Products By Gary | Tom Mills / Jefferson Auto |

| Home Page | Owners Registry | Discussion Forums | ProwlerMall | Event Scrapbooks | About |

| Prowler Products By Gary | Tom Mills / Jefferson Auto |

Click here to return to the Prowler Online Board Main Page |

ProwlerOnline, Plymouth/Chrysler Prowler Discussion Forum ProwlerOnline, Plymouth/Chrysler Prowler Discussion Forum

Technical Questions & Answers Technical Questions & Answers

Ball joint failure at 40 MPH. (Page 6) Ball joint failure at 40 MPH. (Page 6)

|

| Bottom of Page This topic is 6 pages long: 1 2 3 4 5 6 |

next newest topic | next oldest topic |

| Author | Topic: Ball joint failure at 40 MPH. |

Tomcal    POA Site Supporter Prowler Junkie From:Commack, NY, USA |

bryancobb, This may help you with some ideas. Video explains their design concept.

ESMRACE.com This message has been edited by Tomcal on 04-28-2018 at 01:56 PM |

|

bryancobb Prowler Enthusiast From:Cartersville, GA, USA |

That's similar to what I was imagining except for a few subtle details I don't care for. I LOVE the way his tapered bolt shank was done with a steel sleeve and a standard internal-wrenching SHCS. I DO NOT DO NOT like the way his spherical bearing loads into the housing from the top and is only secured by a tight fit and a tiny snap-ring groove. My version loads from the bottom and is prevented from coming out the top at 40 MPH, by a beefy shoulder in the THE BIGGEST difference is my spherical "ROLLER" bearing which actually rolls as the steering wheel is turned, where his plain spherical bearing just slides. It's basically a ball and socket like a regular ball-joint. Here's a picture of the spherical SEE-SAW bearings on the head of my helicopter I built. These are Aurora brand aerospace grade precision spherical bearings. They have closer tolerance fits than standard ones. That's what the guy in the video shows.

quote: This message has been edited by bryancobb on 04-28-2018 at 02:58 PM |

|

bryancobb Prowler Enthusiast From:Cartersville, GA, USA |

I just watched several videos that show rebuildable Aurora spherical bearing ball joints that wore out prematurely. I get the impression that axially loading is not how aurora bearings are meant to be used. They do very well in slightly off-axis radial loading but high side loads wear them out quickly. I still feel the spherical roller bearing is the best kind for this load. |

BradleyG   POA Site Supporter Prowler Junkie From:Dallas, Texas |

Back on the road again!!! 10 months is a long time to be in the garage. Took to the dealer (Dallas Dodge in Dallas). My service adviser knew very little about the Prowler, except what it is. Talked with the Viper/Prowler Technician. He moved here from Denver a few years ago and is very familiar with Prowlers. Made me feel comfortable leaving the car with him. Did a FAST and great job and lowered the labor cost from $450 to $390. Still too much for the job, but with me still recovering from surgery, no way I could have done it. A GREAT BIG THANK YOU TO ROBIN FOR SENDING ME THE SET OF BALL JOINTS. Really, I cannot thank you enough. |

Landscape Doctor      POA Site Supporter Prowler Junkie From:Live Free Or Die State, NH |

Good to hear you are back on the road Bradley.

quote:

|

TFischer                  POA Site Supporter Prowler Junkie From:Texas, USA |

That's awesome! Way to go Robin for helping Brad out. Glad you are back on the road again Brad. |

BradleyG   POA Site Supporter Prowler Junkie From:Dallas, Texas |

There is NO EXCUSE to let this happen to you. We have had plenty of warning. I choose to ignore them and I am very fortunate that I was not hurt and only minor damage to my car. These are replacement ball joints with 95,000 miles on them and I never checked for damage.

|

mslc10      POA Site Supporter Prowler Junkie From:Bulverde, Texas, United States |

Sure looks like uva rays have done their job !! You see any other joints out there that are translucent boots? Let alone an open a-arm that is exposed to sunlight. If we can just find a boot that can replace the translucent boot ,my guess is we’d be set. |

CAT-A-TONIC   POA Site Supporter Prowler Junkie From:SANTA CLARA,CA. |

The boot material was suspect because there have been since the beginning of this ball joint fiasco, indicators that the boot failures were the direct cause. Not so. While they definitely contribute to early ball joint problems, the other side of the coin is the normal pounding the ball joints take in general. So while a different boot material "MAY" stop premature failures, it won't stop long term failures. Realizing this unique problem just necessitates more owner awareness over maintenance in this area. But in saying that, a more durable boot would mean at the very least, we wouldn't have to swap out a ball joints just because of a torn boot.

|

|

Stroker Prowler Junkie From:Sevierville, Tennessee, USA |

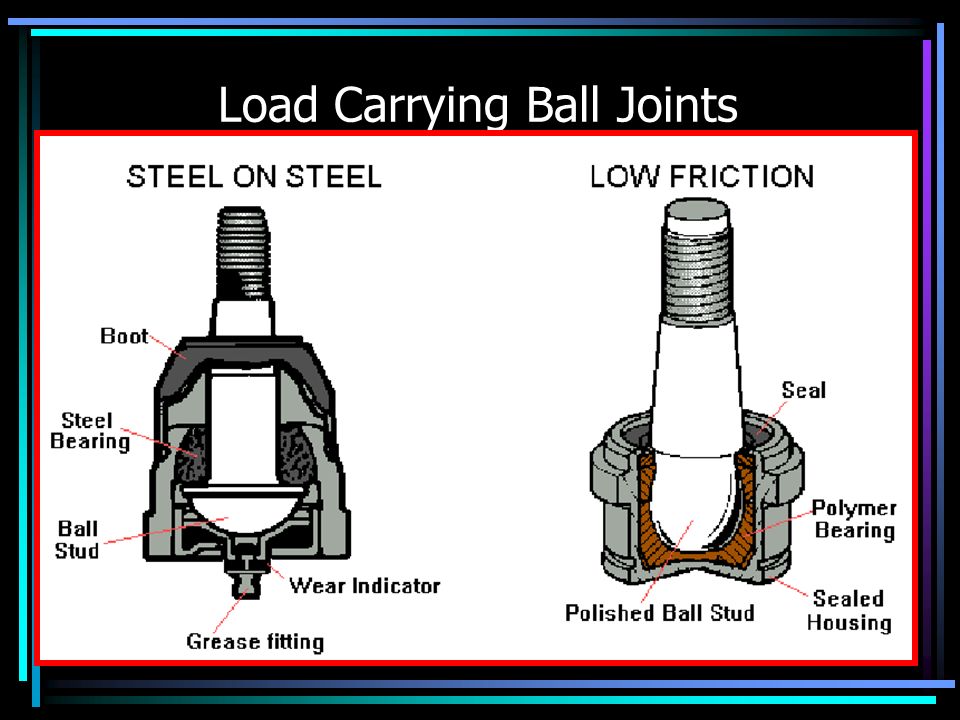

[img] [img]Which one would you like to have? |

CAT-A-TONIC   POA Site Supporter Prowler Junkie From:SANTA CLARA,CA. |

Hi Stroker.......I'm not sure how to interpret your question. What do you mean which one we'd rather have. Our original front lower ball joints don't suffer from a lubrication problem. |

|

Stroker Prowler Junkie From:Sevierville, Tennessee, USA |

The picture will show the left ball joint is assembled from the bottom and the bottom of the stud is larger than the opening at the top. Also has a wear indicator and is able to be greased which flushes any dirt or water away from the wear points. With the right example the safety depends on the bond between the polymer and body and strength of polymer above the ball. If lubrication is not important why do fronts fail and rears not when vehicle has near 50-50 weight distribution? |

Tomcal    POA Site Supporter Prowler Junkie From:Commack, NY, USA |

First... the above illustrations are "Artist Renditions" and should not be confused with actual Engineering "As Built" drawing. If the plastic bearing material wears, it is still retained by metal that is hydraulically formed at manufacturing time around upper part of housing. (Prowler ball joint) Chrysler in their engineering evaluation of failed ball joints determined that rubber boot failure allowing lose of lubricant and contaminants, water being one of them, to enter joint. Rust and contaminates abraded upper area of ball joint resulting in lose of metal, causing ball to pulling free from base. Chrysler only partially addressed rubber boot issue in recall and boots continue to fail. I've posted this Chrysler engineering report many times. They x-rayed, stress tested, you name it. WE KNOW THE FAILURE MODE. And it's really TRW's fault as designer and supplier. Aftermarket folks are doing the engineering on a possible replacement, not us. Better Boot material, lubrication, more metal, whatever. A new rebuildable joint would be ideal. Some aftermarket suppliers use this concept. While in general it's good to through out ideas and theory's, lets leave the engineering to the people who make aftermarket ball joints. Let's focus on those people working with aftermarket suppliers to develop a more robust joint. Thus far, we have POA folks communicating with potential suppliers and POA members providing parts samples. Lets continue to give them our full support. I know I will. This has been a public service message. Now back to your regularly scheduled programing. ... |

ed monahan                   POA Lifetime Site Supporter Prowler Junkie Personal ScrapBook From:Cincinnati, Oh, USA |

The rears do not take anywhere near the pounding that the fronts do. The rears probably do not rotate nearly as far under normal driving circumstances. Then again, I could be totally wrong. |

Tomcal    POA Site Supporter Prowler Junkie From:Commack, NY, USA |

Rear lower ball joint is not subject to torsional loads on boot. (rotational loads) Front boots rotate corresponding to steering maneuvers, stressing boot. Rears do not rotate. Rear lowers can be greased, prolonging life. I'd venture to say rears take close to same pounding as fronts. |

ed monahan                   POA Lifetime Site Supporter Prowler Junkie Personal ScrapBook From:Cincinnati, Oh, USA |

The fronts turn, that is when they take MORE pounding than the rear. Probably not on a straight and level road, I agree. |

This topic is 6 pages long: 1 2 3 4 5 6 All times are CT (US) Top of Page Previous Page |  Return to Technical Questions & Answers next newest topic | next oldest topic Return to Technical Questions & Answers next newest topic | next oldest topic |

|

|

All material contained herein, Copyright 2000 - 2012 ProwlerOnline.com

E-Innovations, LP