Click here to return to the Prowler Online Board Main Page |

ProwlerOnline, Plymouth/Chrysler Prowler Discussion Forum ProwlerOnline, Plymouth/Chrysler Prowler Discussion Forum

General Prowler Discussion General Prowler Discussion

Once again everyone...Thank You!!! Once again everyone...Thank You!!!

|

| Bottom of Page | next newest topic | next oldest topic |

| Author | Topic: Once again everyone...Thank You!!! |

TooHipCat    POA Site Supporter Prowler Junkie From:Londonderry,NH |

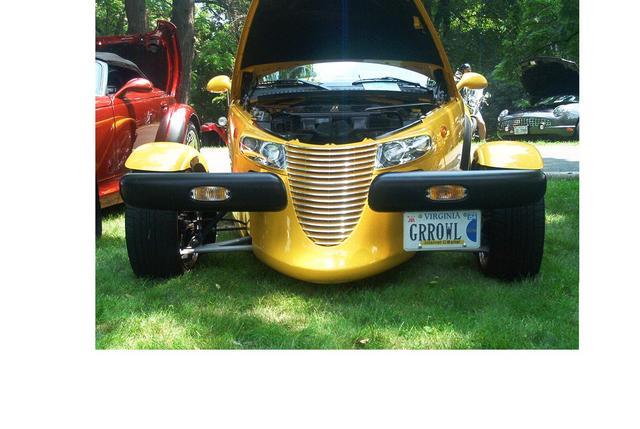

GenoTex and I have been going back and forth with PM's...in addition to everyone else's advice on what to do about installing a front license plate bracket. He even offered to kindly lend me a front license plate bracket for my 97 Cat. I in turn asked him if the bracket was still available that he was referring to. Please see the e-mail I received below from Paul who is also a member of this fantastic POA community: Brian, yes, they are still available. I have attached some pix of the Prowler PlateMount. It is made using laser cut stainless steel and 3M’s most reliable DualLock product which allows you remove and remount the PlateMount many times, if preferred. Cost is $69.95 prepaid to 48 states. Freight quoted for Canada, Alaska, or Hawaii. Mail your personal check to: Paul

I am also including the pics that Paul sent to me showing several views on this bracket. I am passing on this great information to everyone just as GenoTex did for me. Just in case a cop gets on anyone else's case about not having a front plate. Brian |

Paul  POA Site Supporter Prowler Junkie From:Cedarburg, WI USA |

Wouldn't you know it, a Prowler owner with a water-spotted bumper....from the bottom, of course. Sorry about that underside shot. I didn't know it would be posted for everyone but I hope you get the idea despite the ugly garage walls and the water spots under the front bumper. GenoTex is my best salesman. I'm gonna' have to start paying him a commmission. Thanks Mr. Gene! |

GenoTex     POA Site Supporter Prowler Junkie Personal ScrapBook From:Oakfield, WI, USA |

Always A Pleasure, Paul. Great products are Always easy sales  |

|

ZRed99 Prowler Newbie From:St. Paul, MN, USA |

Does the dual lock really hold it in place? I would worry too much about it blowing off. Can it be fastened with screws? |

GenoTex     POA Site Supporter Prowler Junkie Personal ScrapBook From:Oakfield, WI, USA |

Yes it does hold........... and part of the 'point' of using it is to avoid screws/drilling of any kind in the car.  |

GRROWL     POA Site Supporter Prowler Junkie From:Herndon, VA |

quote: quote: |

GRROWL     POA Site Supporter Prowler Junkie From:Herndon, VA |

This is really starting to sound much more complicated than it is. This is a 15-minute job requiring only an electric drill with a 1/4" bit and a portable belt sander or grinder. Here's the procedure: ---------------------- 1. Drill out the 2 pop rivets below the directional signal (all drilling is with a 1/4" bit). 2. Remove the directional signal as if you were replacing the bulb, just let it hang. Drop in 2 bolts (1/4" x 1-1/2") down through the holes you will find behind the signal and out through the pop-rivet holes. 3. Find a piece of 9" long 1" x 2" angle in your choice of materials. Contour the 1" edge to match the front curve of the groove under the bumper (the 2" face will then be hanging down at the rear. 4. Center the bracket below the light opening, drill 2 holes to match the new bolts (should be 5" apart, but check), and bolt on. 5. Drill 2 holes, 1/4", 7" apart, and bolt on the license plate. 6. Re-install the signal. Done! --------------------- Additional (overly complicated) points: A. No metal-working-specific tools were used in the production of this bracket. The portable belt sander worked well with an emory belt to contour the aluminum angle (which was 1/8" thick, by the way), round all of the corners, and ease the edges. I also used it to sand the faces to produce a "brushed" finish. B. You could just as well use stainless steel angle (if you can find it); plastic angle; or bend sheet-metal of your choice. You could also attach with pop-rivets (skip steps 2 and 6) or screw into the pop-rivet holes with 5/16" self-tapping screws. Again, this is over-complicating the issue for such an easy (and good) fix. C. You probably want to stiffen up the plate - I used a clear cover that did the job nicely. You could also use a backer, either the original mount, sheet-metal, plastic or whatever. |

All times are CT (US) Top of Page Previous Page |  Return to General Prowler Discussion next newest topic | next oldest topic Return to General Prowler Discussion next newest topic | next oldest topic |

|

|

Contact Us | Prowler Online Homepage

All material contained herein, Copyright 2000 - 2012 ProwlerOnline.com

E-Innovations, LP