| Bottom of Page | next newest topic | next oldest topic |

| Author | Topic: Ball Joint update 6/8 |

CAT-A-TONIC   POA Site Supporter Prowler Junkie From:SANTA CLARA,CA. |

Talked with Glen at Rare Parts. They have assigned a part number for these ball joints. They are into the design and internal inspection of them as well. Looks like there is discussion regarding having them grease-able with a zerk. Is there any one out there that has some good clear front end suspension pictures that center around out lower BJ and clearance between the bottom of out BJ's and the rim it self? If anyone has, could you please PM me and I will give you my regular email address so you can send me the pic's and I will forward them to Glen. I need to have the pic's myself for reference when dealing with Rare Parts. Thanks for help on this. WE ARE moving forward and after talking with Glen I am convinced that we will get a replacement ball joint that is going to offer better performance.(better boot included) Thanks......Mike |

alrtg          POA Site Supporter Prowler Junkie From:Westminster, MD, USA |

If clearance is a big concern regarding the fitting becoming damaged during regular use, I have a suggestion. It would be nice to have the new ball joint designed to accept a zerk fitting even it it does not actually get one installed. I would suggest that the vendor provide the ball joint with a filler (Screw/Bolt) that could be removed and a zerk installed for lubrication as needed then removed and reinstall the filler. This would give the consumer the option. JMO I found an item for sale on e-bay that illustrates my thought. http://www.ebay.com/itm/1-4-28x1- 4-Button-Head-Hex-Socket-Cap-Screws-Alloy-Steel-Black-25/191736322594?hash=item2ca4601a22:g:3wIAAOSw5VFWQ1zn

This message has been edited by alrtg on 06-08-2018 at 06:05 PM |

phil2237 POA Site Supporter Prowler Junkie From:PLACENTIA CALIFORNIA |

The joints are not suffering from grease loss until they rupture, The problem is the joints are being hammered. Drive your Prowler and watch the top of the drivers side fender. That is the hammering effect they are taking. Although they should have a zerk fitting as maybe that will extend their wear a while longer. |

|

Larry Lord Prowler Junkie Personal ScrapBook From:Colton, CA |

Every ball joint on every car ever made gets "hammered". That's just the nature of the beast. The loads on a Prowler ball joint are much lower than on many cars. Ball joints are normally designed to handle the load requirements. "Hammering" is not the problem. The design load factor and boot failure with resulting lack of lubrication and internal corrosion are the true problems. ------------------ This message has been edited by Larry Lord on 06-08-2018 at 08:49 PM |

mslc10      POA Site Supporter Prowler Junkie From:Bulverde, Texas, United States |

quote: The fender is vibrating more than the actual suspension. It does so due to the mounting bracket is only attached on the inner side. This cantilever style does not allow for a reinforcing mount on two points . If you look at a motor cycle it’s fender is mounted on both sides....that’s why the prowler fender has all that vibration, it does not have a two point mount (inside AND outside). This message has been edited by mslc10 on 06-08-2018 at 09:41 PM |

robin     POA Site Supporter Prowler Junkie From:St Thomas Ontario Canada |

One is a piece of shrink wrap other is a tea light (candle)

This message has been edited by robin on 06-09-2018 at 10:24 AM |

CAT-A-TONIC   POA Site Supporter Prowler Junkie From:SANTA CLARA,CA. |

Robin.......those pic's are what I need! PERFECT!! |

CAT-A-TONIC   POA Site Supporter Prowler Junkie From:SANTA CLARA,CA. |

Several of our theories seem to make sense. We've seen as of late ball joint problems where the stem has pulled out of the housing and there has been no boot failure. But here goes one more: say a basketball player is standing on the court upright and bouncing the ball. He throws it to the floor and it returns to his hand and repeats over and over. Say it's between 4 and 5 feet between his hand and the floor. NOW.....have him get down on his knees and measure so his hand is now dribbling the ball 1 foot off the floor. The ball is going to be bouncing at a much faster and firmer rate. The comparison I see in this, is his hand is our control arm and his wrist that is taking all the beating at this increased rate, is our ball joint. Our suspension is like at the 1 foot level. If the basketball player could keep this up for an extended period something will eventually give. And I think the obvious is his wrist as it is taking all the punishment. And the faster he tries to dribble the ball the more strain his wrist will take, until failure. This does not address the boot failure, it's just meant to possibly describe how the ball joints are being worked. And I'm sure based off terrain, speed and frequency time frame enters into the picture regarding when a failure might occurre. Just another theory. If I'm all wet let me know. In the mean time....... onward!!!!!! |

DublinOH      POA Site Supporter Prowler Junkie From:McMurray, Pa, USA |

I'm not expert on suspension components and design, but I'm not sure that the prowler ball joints are subjected to forces any different that any other ball joint on any other vehicle. They all take a beating. You just can't see it beacuse the fenders are stationary on all other vehicles. Think about an off road race truck...I don't know what effect the rocker arm system has on the lower ball joint versus a coil, strut, or leaf setup. My personal opinion is that the redesigned ball joints improved the strength of the assembly by beefing up the girth. I'm not sure the boot tearing has been addressed, which most likely leads to corrosion and failure. Once the boots leak, water lays in there and contaminates the grease. Good boots equal a sealed system void of water. I would think the failure rate would be higher on vehicles used in close proximity to salt water, and vehicles driven in winter months where corrorion is more prominent. |

ed monahan                   POA Lifetime Site Supporter Prowler Junkie Personal ScrapBook From:Cincinnati, Oh, USA |

Most cars have a shock absorber a LOT closer to the wheel. Is this part of the equation, also? |

ed monahan                   POA Lifetime Site Supporter Prowler Junkie Personal ScrapBook From:Cincinnati, Oh, USA |

Sorry, my computer seems to be posting EVERYTHING twice. Sometimes I get a message, "we have flood control" when I am not attempting to post. This message has been edited by ed monahan on 06-09-2018 at 07:27 PM |

phil2237 POA Site Supporter Prowler Junkie From:PLACENTIA CALIFORNIA |

quote: Have to disagree with you Larry as almost every car , or truck has a coil or shock mounted to the lower A Arm to soften the hammering that the ball joint takes. A shock or some kind of coil would greatly increase the life of the lower ball joint. Several of the failed ball joints still had the grease on them when they failed. |

DublinOH      POA Site Supporter Prowler Junkie From:McMurray, Pa, USA |

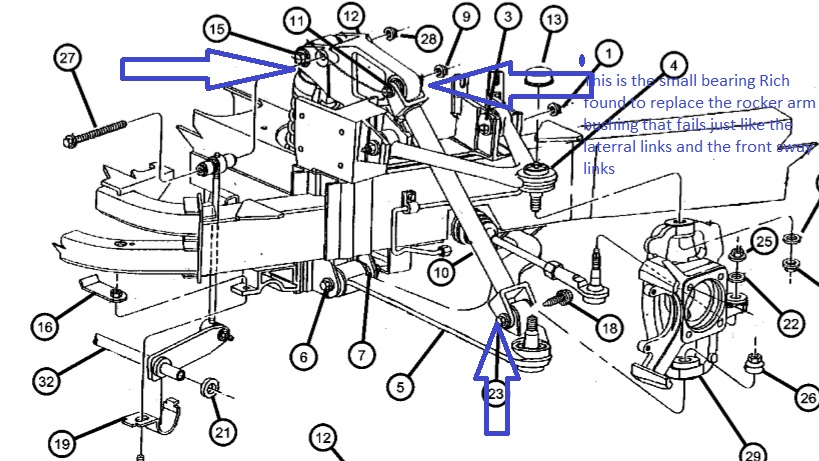

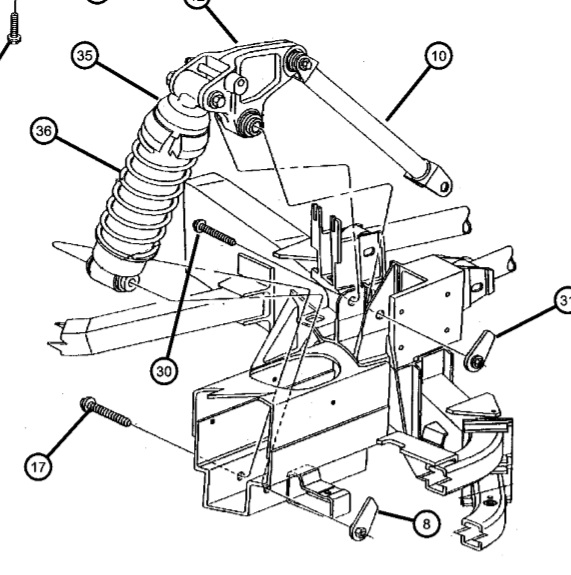

http://www.turnology.com/tech-stories/brakes-suspension/appeal-pushrod-suspension/ The prowler also has a shock/spring to dampen the ride, it is just located inboard and utilizes a push rod / rocker arm set up - like indy cars. |

robin     POA Site Supporter Prowler Junkie From:St Thomas Ontario Canada |

great demo DublinOH If we had quality parts to start off with could be a different story.

these rocker arm bushing deteriorate just link the other Pivital parts we need for the front suspention to work together.....

This message has been edited by robin on 06-10-2018 at 11:00 AM |

mslc10      POA Site Supporter Prowler Junkie From:Bulverde, Texas, United States |

I think we have beat or “hammered” the dead horse! Cat will always say coil or shock will prevent the hammering.... Others will say it is all the same as other vehicles.... So how many ford rangers, crown Vic’s have you heard seeking as they go down the road....plenty!! All ball joints ...all shocks ,springs, or struts close to ball joint. It’s just a crappy designed boot and or orientation of bj in spindle or a arm....

|

Tony Goertz                   POA Site Supporter Administrating Kat Personal ScrapBook From:Lucan1, Ontario, Canada |

I recall GM had trouble with front ends on pickup trucks when they first went to 20"rims and low profile tires on the Denali model. The low profile tires didn't give as much "cushion" as the 18" wheels and the front ends failed early. Food for thought !! Our ball joints feel every little bump.... |

Tomcal    POA Site Supporter Prowler Junkie From:Commack, NY, USA |

I sure hope final design has a grease fitting. If we're starting from scratch, why not! |

All times are CT (US) Top of Page Previous Page |  Return to General Prowler Discussion next newest topic | next oldest topic Return to General Prowler Discussion next newest topic | next oldest topic |

|

|

Contact Us | Prowler Online Homepage

All material contained herein, Copyright 2000 - 2012 ProwlerOnline.com

E-Innovations, LP